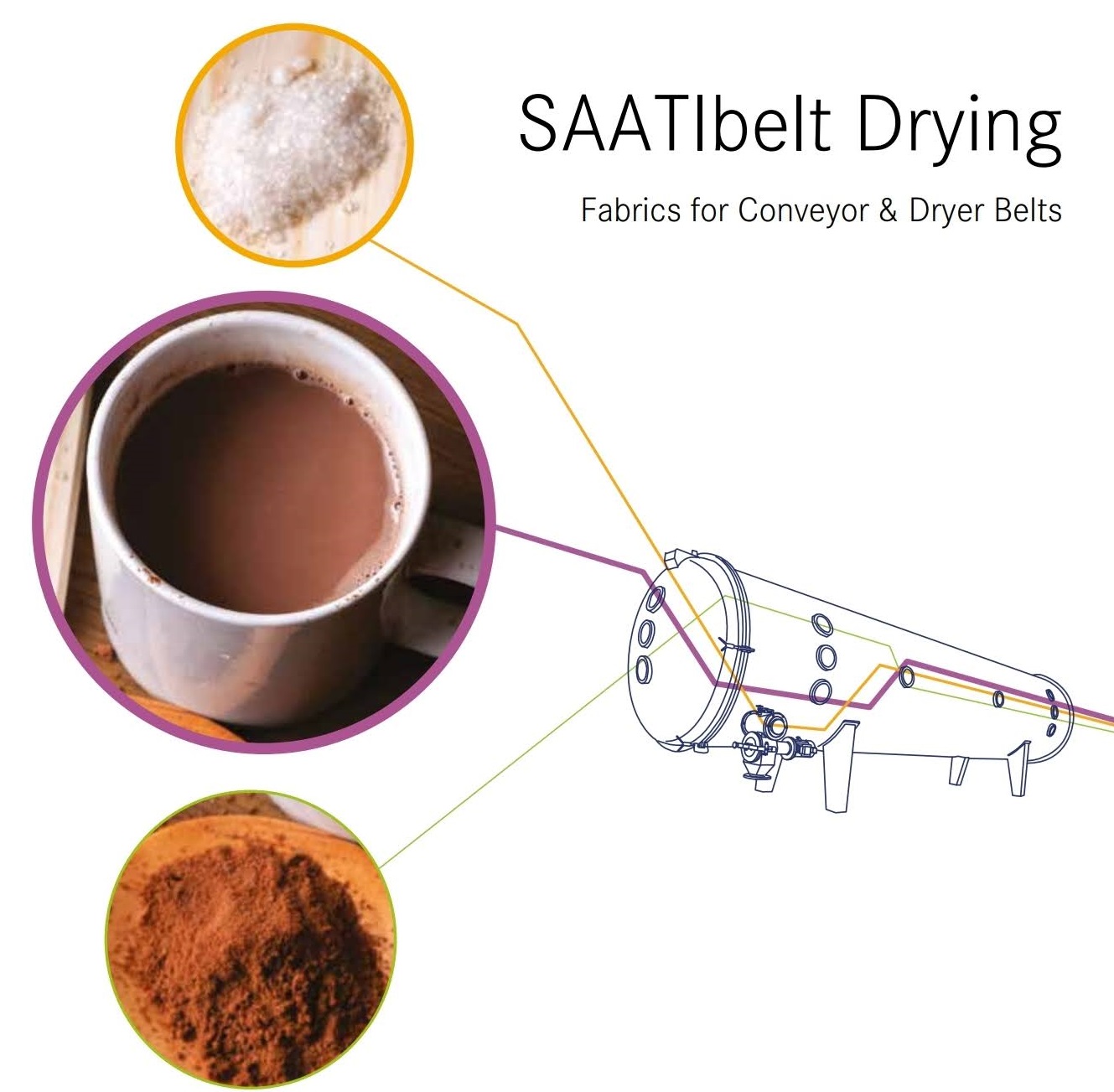

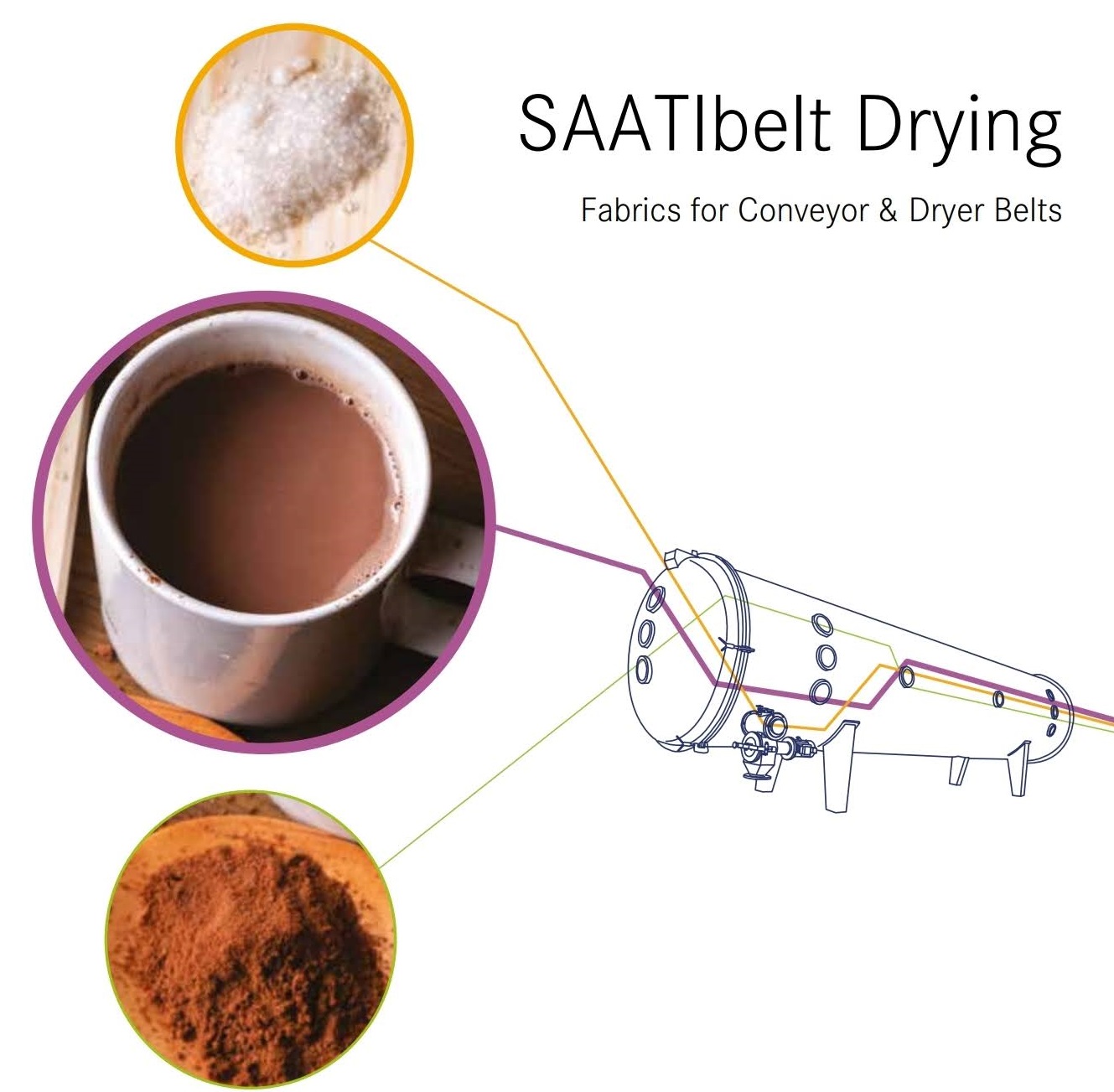

BELTS FOR VACUUM DRYERS

A large range of food and beverage products are produced with continuous vacuum drying processes. SAATI produces a wide range

of precision woven mesh from more than 85 years with a specific focus on the food market and proud partnerships with the major

food groups. SAATIbelt Drying is the dedicated line for continuous drying of several types of products like malt drink powder, juice

concentrate, vegetables and meat products (broth), bakery products (yeast), hydrolyzed vegetable proteins, and so on. The high

precision weaving process allows SAATI to supply a very consistent product with both uniform pore size and air permeability that

are key factors in the optimized drying process. Several field tests with major food groups highlight the excellent results achieved

with SAATIbelt meshes in terms of both lifetime and productivity.

The special weaving construction gives an excellent cake release and flexibility, with consequent production efficiency improvements;

the high tech thermal treatment is able to give stability and high temperature resistance for a longer service life.

SAATI products are manufactured in accordance with UNI ISO 9001 standards. SAATI also takes great care regarding food safety

and food regulation, SAATIbelt drying products are made with FDA approved polymers and they are compliant with EU 10/2011

regulations.

SAATI Belt Drying Features :

- Mechanical and Thermal Stability

- For optimal belt tensioning, product distribution, and long product life

- Hydrolysis Resistance –

- Better lifetime and resistance to drying and washing processes

- Smooth Surface

- In order to prevent clogging and to improve dryer productivity

- FDA Polymer Approved

- Conformity Declaration upon request

- Compliant with EU 10/2011

- Conformity Declaration upon request

SAATI is able to fabricate finished drying belts, ready to be installed. This is a key factor that allow us to control all the aspects from

the raw material to the finished product. All belt components can be customized based on the final application in order to be flexible

and to supply a product that can meet all customer technical requirements; splicing are fabricated to facilitate the installation and

maintenance procedure, and edges give the right structure to the belt and protect against abrasion damage.

DOWNLOAD BROCHURE